A Comprehensive Analysis of the Air India Flight 171 Accident: A Confluence of Systemic Risk

1229

The landscape of modern aviation safety was irrevocably altered on June 12, 2025, with the catastrophic loss of Air India Flight 171. The incident, which occurred just moments after departure from Ahmedabad, India, was not only a profound human tragedy but also a watershed moment for the global aviation industry. It marked the first fatal crash and complete hull loss of a Boeing 787 Dreamliner, an aircraft model that, despite a well-documented history of production challenges and safety concerns, had maintained a fatality-free service record for over a decade.1 The crash claimed the lives of 241 of the 242 people on board and at least 38 individuals on the ground, representing one of the deadliest aviation disasters in India's history.4

The fundamental question—"Why did it crash?"—demands an answer that extends far beyond a single point of failure. A comprehensive analysis of the available evidence suggests that the disaster was not a random accident but rather the tragic culmination of a complex interplay of factors. These include the specific service history of the aircraft involved, systemic and long-standing quality control deficiencies at the manufacturer, and the broader operational context of the airline. This report seeks to deconstruct the multifaceted nature of the Air India Flight 171 accident. It will provide a detailed reconstruction of the event, analyze the history of the specific aircraft and the broader Boeing 787 program, examine the corporate and operational environments of both Air India and Boeing, and detail the ongoing official investigation. The analysis will demonstrate how a chain of latent risks, potentially originating on the factory floor years earlier, may have led to the catastrophic failure in the skies over Ahmedabad.

Table 1: Air India Flight 171 - Incident Fact Sheet

| Fact | Detail |

|---|---|

| Flight | Air India Flight 171 (AI171 / AIC171) 4 |

| Date and Time of Crash | June 12, 2025, 13:38 IST (08:08 UTC) 4 |

| Aircraft Type | Boeing 787-8 Dreamliner 4 |

| Aircraft Registration | VT-ANB 4 |

| Route | Sardar Vallabhbhai Patel International Airport, Ahmedabad (AMD) to London Gatwick Airport (LGW) 4 |

| Crash Location | B. J. Medical College Hostel, Meghaninagar, Ahmedabad, India 4 |

| Fatalities (Onboard) | 241 (out of 242 occupants) 6 |

| Fatalities (Ground) | 38+ 4 |

| Survivors (Onboard) | 1 6 |

| Flight Crew | 2 Pilots, 10 Flight Attendants 4 |

| Lead Investigating Agency | Aircraft Accident Investigation Bureau (AAIB), India 5 |

The Anatomy of a Disaster: The Final Minutes of Flight AI171

The sequence of events that led to the destruction of Air India Flight 171 unfolded with terrifying speed, leaving the flight crew with almost no time to react or recover. The flight's final moments, pieced together from official statements, flight tracking data, and eyewitness accounts, paint a picture of a sudden and catastrophic loss of control.

Departure and Initial Climb

On the afternoon of June 12, 2025, Air India Flight 171 prepared for its long-haul journey to London. At 13:38 Indian Standard Time (IST), the Boeing 787-8, registered VT-ANB, commenced its takeoff roll from runway 23 at Ahmedabad's Sardar Vallabhbhai Patel International Airport.4 Meteorological reports from the time of the departure indicated stable weather and clear visibility, effectively ruling out adverse weather conditions as a contributing factor to the accident.4 The initial phase of the flight appeared routine as the aircraft lifted off the runway.

Distress Call and Loss of Control

The normalcy of the flight was shattered within moments of becoming airborne. Shortly after takeoff, the flight crew, commanded by Captain Sumeet Sabharwal, transmitted a "mayday" distress call to air traffic control.10 The content of this desperate transmission was chillingly specific: the crew reported a "loss of power and thrust".4 This communication was the last the world would hear from Flight 171. Subsequent calls from air traffic controllers went unanswered as the aircraft's situation deteriorated rapidly.10

Flight Path Anomaly

Data from the aircraft's Automatic Dependent Surveillance-Broadcast (ADS-B) transponder provides a stark, digital record of the flight's struggle. The aircraft reached a maximum altitude of just 625 feet above the ground before its vertical speed became negative and it began to descend.4 This extremely low peak altitude indicates that the emergency occurred almost immediately after liftoff.

The flight path anomaly was corroborated by multiple videos captured by eyewitnesses on the ground. These recordings show the aircraft failing to establish a positive rate of climb. In a particularly telling detail, the aircraft appeared to be pitching its nose upwards even as it was losing altitude and descending toward the ground.4 This visual signature is a classic characteristic of a low-altitude aerodynamic stall. When an aircraft loses forward thrust, its airspeed decays. Pilots may instinctively pull back on the controls to raise the nose and maintain lift, but if the airspeed continues to drop, the angle of the wings relative to the oncoming air (the angle of attack) can become too great. At this point, the airflow separates from the wing surface, lift is lost catastrophically, and the aircraft falls from the sky regardless of its nose-up attitude. The entire event, from takeoff to the final loss of transponder signal, occurred in approximately 30 to 60 seconds.4

Impact and Aftermath

The brief, tragic flight of AI171 ended 1.5 kilometers from the end of the runway.4 The aircraft plunged into the densely populated Meghaninagar district, directly impacting the hostel and dining complex of the B. J. Medical College.6 The impact, fueled by the large quantity of jet fuel intended for the long flight to London, resulted in a massive explosion and an intense post-crash fire that sent a thick plume of black smoke into the sky.4

The human cost was devastating. All 12 crew members and 229 of the 230 passengers on board were killed, a list of victims that tragically included the former Chief Minister of Gujarat, Vijay Rupani.5 The disaster extended to the ground, where at least 38 people, many of them medical students in the hostel, lost their lives.4 In a singular miracle amid the carnage, one passenger, a British national, survived the crash after the section of the fuselage where he was seated reportedly broke away and came to rest on the ground floor of the building, allowing him to escape.4 The extremely short timeline of the emergency, unfolding at a very low altitude, points away from a manageable issue like a single engine failure—a scenario for which pilots are extensively trained—and strongly suggests a sudden, unrecoverable event, such as a near-simultaneous failure of both engines or a complete loss of flight control.

The Aircraft in Focus: A History of VT-ANB and the Dreamliner Program

To understand the potential root causes of the Flight 171 disaster, it is imperative to examine not only the final flight but also the history of the specific aircraft, VT-ANB, and the broader context of the Boeing 787 Dreamliner program, which has been marked by both technological innovation and significant production controversies.

Service History of VT-ANB

The aircraft involved in the accident was an 11-year-old Boeing 787-8, registered VT-ANB.4 Its service history reveals several factors that place it in a higher-risk category and are of critical interest to investigators.

The aircraft was an early-build model, having been assembled at Boeing's Everett factory in 2011.3 However, it was not delivered to Air India until January 2014, a significant delay attributed to "pre-delivery issues" that required more than two years of storage and rework.3 According to a pilot involved in its delivery, this particular airframe was also approximately five tonnes heavier than Boeing had promised, which negatively impacted its operational efficiency.15

Throughout its decade of service, the aircraft accumulated over 41,000 flight hours and performed nearly 8,000 takeoff and landing cycles, a utilization rate considered average for an aircraft of its age.7 Critically, VT-ANB had a documented history of in-service technical problems. In November 2021, while operating a flight from London to Hyderabad, the aircraft was forced to divert to Ankara, Turkey, due to a fuel leak.15 It also experienced other "teething troubles" common to early-production Dreamliners, such as windshield cracks.15 This history of both pre-delivery quality issues and in-service technical faults, particularly a fuel system problem, establishes a pattern of concern specific to this airframe.

The Boeing 787 Dreamliner: Innovation and Troubled Production

The Boeing 787 Dreamliner was introduced as a revolutionary aircraft, hailed for its fuel efficiency and passenger comfort. Its design made extensive use of lightweight carbon-fiber composite materials for the fuselage and wings, and it was the first airliner to rely heavily on advanced electrical systems powered by lithium-ion batteries.14 However, this innovation was accompanied by a troubled production and service history.

The most significant early operational problem occurred in January 2013, when the entire global fleet of 787s was grounded by the U.S. Federal Aviation Administration (FAA) and other international regulators.2 This unprecedented action was taken in response to two separate incidents of fire caused by the overheating of the aircraft's lithium-ion batteries. The grounding lasted for more than three months until Boeing developed and certified a redesigned battery containment system.14

More recently, the 787 program has been plagued by systemic manufacturing quality flaws. Between May 2021 and August 2022, Boeing was forced by the FAA to halt all deliveries of new 787s for over a year.18 This stoppage was due to the discovery of multiple production defects, including improperly filled microscopic gaps between sections of the composite fuselage and the use of faulty titanium components that did not meet specifications.18

The Whistleblower Allegations

The concerns over production quality were amplified by a series of credible and alarming allegations from Boeing insiders. These whistleblowers painted a picture of a corporate culture that prioritized production speed over safety, leading to dangerous shortcuts on the assembly line.

John Barnett, a former quality manager at Boeing's 787 plant in South Carolina who died in March 2024, had filed a whistleblower complaint in 2019. He alleged that workers under pressure were deliberately fitting substandard parts to aircraft, that there were serious unresolved issues with the wiring of flight control systems, and that testing revealed a potential 25-percent failure rate in the emergency oxygen systems.21

In early 2024, another Boeing engineer, Sam Salehpour, came forward with even more disturbing allegations specific to the 787's construction. He claimed that sections of the aircraft's composite fuselage were being improperly fastened together, creating structural gaps that exceeded design limits.18 Salehpour alleged that to make the ill-fitting sections align, workers resorted to "brute force," including jumping on the parts, which could compromise the long-term structural integrity of the airframe and potentially lead to a catastrophic failure in flight.18 These claims were deemed serious enough that in May 2024, the FAA ordered Boeing to conduct new inspections on all 787s still in production and to develop a plan to address the in-service fleet.18

The confluence of these factors—an early-build aircraft with a history of pre-delivery and in-service faults, manufactured during a period of alleged quality control lapses—makes the history of VT-ANB a critical focus of the investigation. The pilot's mayday call of "loss of power" directly intersects with two plausible evidence-based scenarios: a catastrophic failure of the fuel system, which connects to the aircraft's documented 2021 fuel leak, or a failure of the electronic engine control systems, which could be linked to the very wiring issues alleged by whistleblower John Barnett.

Table 2: Timeline of Key Events for the Boeing 787 Dreamliner Program

| Date | Event |

|---|---|

| 2011 | Boeing 787 enters commercial service.11 |

| Jan 2013 | FAA grounds the entire global 787 fleet due to risk of fire from lithium-ion batteries.2 |

| Apr 2013 | FAA approves battery redesign; 787 flights resume.2 |

| 2019 | Whistleblower John Barnett alleges serious quality control lapses in 787 production, including wiring and substandard parts.18 |

| May 2021 - Aug 2022 | FAA halts all 787 deliveries due to major manufacturing defects, including fuselage gaps.18 |

| Jan 2024 | Whistleblower Sam Salehpour alleges improper fuselage assembly on the 787 could lead to structural failure.18 |

| Mar 2024 | A LATAM Airlines 787 experiences a sudden plunge, injuring 50 people, attributed to pilot seat movement.18 |

| May 2024 | FAA orders Boeing to reinspect 787s in production and create a plan for the in-service fleet based on whistleblower claims.18 |

| June 12, 2025 | Air India Flight 171 crashes, marking the first fatal accident and hull loss for the Boeing 787.1 |

Corporate and Operational Context: Air India and Boeing

The crash of Flight 171 cannot be analyzed in a vacuum. It occurred at a critical juncture for both Air India and Boeing, with each organization facing immense internal pressures and external scrutiny that form an essential part of the accident's context.

Air India: A Turnaround Under Pressure

For decades, Air India operated as a state-owned enterprise, a period marked by financial losses and a mixed safety record.14 The airline and its subsidiary, Air India Express, were involved in several fatal accidents, most notably the 2010 runway overrun in Mangalore that killed 158 people and the 2020 runway excursion in Kozhikode that killed 21. Both of these prior accidents involved Boeing 737-800 aircraft and occurred during the landing phase.22

In 2022, a new chapter began when the Indian conglomerate Tata Group acquired the airline, returning it to private ownership and launching an ambitious, high-profile turnaround strategy.22 This transformation involved a massive rebranding effort and record-breaking orders for hundreds of new aircraft from both Boeing and Airbus, including more 787 Dreamliners.22 However, this rapid push for modernization and market share has drawn criticism. Some industry analysts have raised concerns that the intense focus on rebranding and expansion may have overshadowed the more fundamental and challenging work of overhauling the airline's deep-seated operational and maintenance cultures.25 Such a high-pressure environment can create risks, where production targets and on-time performance could, if not managed carefully, take precedence over meticulous safety and maintenance protocols.

Table 3: History of Major Air India Accidents (2010-Present)

| Date | Flight | Aircraft | Location | Fatalities | Summary |

|---|---|---|---|---|---|

| May 22, 2010 | Air India Express Flight 812 | Boeing 737-800 | Mangalore, India | 158 | Overshot runway on landing.23 |

| August 7, 2020 | Air India Express Flight 1344 | Boeing 737-800 | Kozhikode, India | 21 | Skidded off runway on landing.23 |

| June 12, 2025 | Air India Flight 171 | Boeing 787-8 | Ahmedabad, India | 241 (+38 on ground) | Crashed after takeoff; loss of power reported.4 |

Boeing: A Systemic Crisis of Confidence

For Boeing, the crash of Flight 171 is another devastating blow to a reputation already in tatters. The disaster occurred against the backdrop of the deepest crisis in the company's century-long history. This crisis began with the two crashes of its 737 MAX aircraft in October 2018 and March 2019, which killed a total of 346 people.7 Investigations revealed that those crashes were caused by a flawed flight control system, known as MCAS, that Boeing had concealed from pilots and regulators.

The fallout from the 737 MAX scandal was compounded by a series of subsequent high-profile quality control failures. The most alarming of these occurred in January 2024, when a door plug panel blew out of the fuselage of an Alaska Airlines 737 MAX mid-flight.21 These events have subjected Boeing to intense scrutiny from regulators, lawmakers, and the public, fueling accusations that the company's corporate culture had shifted to prioritize production targets and shareholder value over engineering integrity and safety.7

Immediate Post-Crash Operational Responses

The crash immediately sent shockwaves through the industry, prompting swift action from regulators and creating heightened sensitivity around 787 operations. Just four days after the Ahmedabad disaster, another Air India Boeing 787, operating as Flight AI315 from Hong Kong to New Delhi, had to turn back shortly after takeoff due to a suspected "technical issue".27 While the aircraft landed safely, the incident amplified public concern and intensified scrutiny of the airline and the aircraft model.28

In response to the crash, India's Directorate General of Civil Aviation (DGCA) ordered immediate, enhanced safety inspections on Air India's entire fleet of 33 remaining Boeing 787 Dreamliners.6 These checks were highly specific, focusing on the GEnx engines, fuel systems, electronic engine controls, and flight control systems.10 By June 16, 2025, sources reported that inspections on 22 of the aircraft had been completed and had found "nothing alarming".5 While seemingly reassuring, this finding could be misleading. If the root cause of the AI171 crash was a latent manufacturing defect specific to early-build aircraft like VT-ANB, a standard maintenance inspection on the rest of the fleet, which is on average younger, would not necessarily detect such a flaw. The absence of a fleet-wide problem does not exonerate the manufacturer; rather, it may serve to narrow the focus of the investigation onto the specific production vintage and history of the crashed airframe.

The Search for Answers: The Official Investigation

In the aftermath of the disaster, a multi-national and multi-agency investigation was launched to definitively determine the cause. The process is governed by international standards and brings together experts from around the world to analyze the evidence and prevent future accidents.

The Investigative Bodies

The formal investigation is being led by India's Aircraft Accident Investigation Bureau (AAIB), the government body responsible for investigating aviation accidents in the country.8 In accordance with international protocol established under Annex 13 of the Convention on International Civil Aviation, the lead agency is assisted by accredited representatives from the state of the aircraft's manufacturer. Consequently, a "go team" from the U.S. National Transportation Safety Board (NTSB) was dispatched to Ahmedabad to assist the AAIB.4 Given that 53 British nationals were among the passengers, the United Kingdom's Air Accidents Investigation Branch (AAIB) also sent investigators to support the probe.4 Boeing, as the manufacturer of the airframe, and General Electric, as the manufacturer of the GEnx engines, are also providing technical expertise and support to the investigation.8

The "Black Boxes": Critical Evidence Recovered

The most critical pieces of evidence in any modern air crash investigation are the aircraft's two flight recorders, colloquially known as "black boxes." Despite the intensity of the impact and post-crash fire, search teams successfully recovered both the Flight Data Recorder (FDR) and the Cockpit Voice Recorder (CVR) from the wreckage within days of the accident.4

The FDR on a technologically advanced aircraft like the Boeing 787 is immensely powerful, capturing thousands of distinct parameters per second. This data—covering everything from engine performance and control surface positions to autopilot status and system warnings—allows investigators to create a precise, second-by-second digital simulation of the flight's final moments.31 The CVR records all conversations and audible sounds within the cockpit, providing invaluable insight into the flight crew's actions, their understanding of the emergency, and any alarms that may have sounded. The analysis of these two recorders will form the core of the technical investigation.

The Regulatory Response and Timelines

In parallel with the AAIB's technical investigation, the Indian government has established a separate high-level committee to conduct a broader review of national aviation safety policies and standard operating procedures.10 This initiative is designed to identify and rectify any systemic weaknesses in India's aviation oversight.

The Indian Civil Aviation Minister announced that this government panel would issue a report within three months.4 Under ICAO rules, the AAIB is required to publish a preliminary report within 30 days of the accident. However, the final, comprehensive accident report, which will detail the full causal chain and make formal safety recommendations, is a much more lengthy process. Based on the complexity of this accident, experts anticipate that the final report could take more than a year to complete.31 The specific checks mandated by the DGCA on the rest of the 787 fleet in the immediate aftermath of the crash provide a clear roadmap to the investigators' initial suspicions. The directive to inspect fuel parameter monitoring, electronic engine control systems, engine fuel actuators, and flight controls is not a random list.17 It is a direct reflection of the initial evidence, strongly indicating that the inquiry is focused on a catastrophic failure within the aircraft's propulsion and control systems.

Synthesis and Forward-Looking Analysis

While the official investigation will take many months to reach a definitive conclusion, the body of available evidence allows for the formulation of a robust primary hypothesis and an analysis of the accident's profound implications. The crash of Air India Flight 171 was likely not a singular event but the product of a causal chain that may have begun years earlier on a factory floor.

The Primary Hypothesis: Catastrophic Propulsion System Failure

Converging lines of evidence—the pilot's mayday call of "loss of power and thrust," the aircraft's inability to climb, and the visual signature of a low-altitude stall—all point to a sudden, complete, and unrecoverable failure of the aircraft's propulsion system.4 Within this primary hypothesis, two leading scenarios, which are not mutually exclusive, emerge as the most probable avenues of investigation:

- A Fuel System Failure: This scenario considers a catastrophic interruption of the fuel supply to both engines. This line of inquiry is given significant weight by the specific history of the crashed aircraft, VT-ANB, which was diverted in 2021 due to a fuel leak.15 This past incident raises the critical question of whether an underlying vulnerability in the fuel system was fully understood and rectified, or if a latent defect remained that ultimately led to a more devastating failure.

- An Engine Control System Failure: This scenario focuses on a failure of the complex electronic systems that control the engines. A modern jet engine is managed by a Full Authority Digital Engine Control (FADEC) system. A failure of this system, or the wiring that connects it to the cockpit and engine sensors, could lead to a complete loss of engine control. This hypothesis aligns directly with the specific warnings of Boeing whistleblower John Barnett, who alleged that shoddy wiring practices and metal debris could lead to "catastrophic" electrical failures.18

The Chain of Causation: From Factory Floor to Final Flight

The root cause of the Flight 171 disaster likely extends far beyond the immediate technical failure that occurred on June 12, 2025. A plausible causal chain can be constructed, linking systemic issues to the final, tragic outcome:

- Latent Condition: The chain may have begun with a latent manufacturing defect introduced during the aircraft's assembly between 2011 and 2014. This period aligns with the time frame during which whistleblowers alleged that Boeing's production processes were compromised by a focus on speed over quality.18

- Contributing Factors: This latent condition may have remained dormant for years, potentially exacerbated by gaps in the airline's maintenance program. It is possible that symptoms of the underlying defect, such as the 2021 fuel leak, were treated as isolated incidents rather than indicators of a deeper, systemic problem, a risk potentially heightened by the pressures of Air India's rapid corporate turnaround.15

- Triggering Event: The final link in the chain would be an unknown stressor during the takeoff phase of Flight 171—a phase of flight that places maximum demand on the engines and airframe. This stressor could have caused the latent defect to finally manifest as a catastrophic and unrecoverable failure.

Broader Implications for the Aviation Industry

The loss of Air India Flight 171 carries profound and far-reaching implications that will resonate throughout the aviation industry for years to come.

- For Boeing: The crash is a calamitous event. As the first fatal accident involving the 787 Dreamliner, it shatters the key selling point of a program that, despite its production troubles, had maintained an impeccable safety record.20 It gives terrifying credence to the most serious warnings from whistleblowers and raises existential questions about the integrity of Boeing's production system and the long-term airworthiness of its aircraft, particularly the hundreds of early-build 787s operating worldwide.

- For Air India: The disaster is a tragic setback for the airline's ambitious turnaround. It places its safety culture, maintenance practices, and operational oversight under an intense and unforgiving international spotlight, threatening to undermine the progress made in rebranding and modernizing the carrier.23

- For Regulators: The crash is a stark reminder of the limitations of reactive oversight. It challenges regulators like the FAA and the DGCA to move beyond post-incident inspections and develop more robust, proactive systems for overseeing manufacturers' production quality from the outset. It underscores the critical need for regulators to take whistleblower allegations with the utmost seriousness and to foster a culture where safety, not production quotas, is the paramount priority.

Conclusion

While the precise sequence of mechanical failures that doomed Air India Flight 171 awaits determination by the official investigation, the evidence available paints a deeply troubling picture. The crash was almost certainly not a random, unpredictable accident. It appears to be the tragic and foreseeable outcome of a confluence of intersecting risks: an early-build aircraft with a documented history of technical issues, a flagship program at a manufacturer plagued by a systemic crisis of quality control, and an airline operating under the immense pressure of a corporate transformation.

The mayday call reporting a loss of power, combined with the aircraft's brief and uncontrolled flight, points overwhelmingly toward a catastrophic failure in the propulsion system. Whether this was triggered by a flaw in the fuel system or the engine control electronics is the central question for investigators. However, the answer to "why" it crashed likely lies not just in the broken parts recovered from the wreckage in Ahmedabad, but in the decisions made in boardrooms and on factory floors years earlier.

The loss of 279 lives demands absolute transparency from both Boeing and Air India. It requires robust and decisive action from global regulators to ensure that the systemic failures that contributed to this disaster are identified and permanently rectified. The integrity of the global aviation system, and the public's trust in it, depends on a thorough, honest, and unflinching examination of how this tragedy was allowed to happen. The memories of the passengers, crew, and ground victims of Flight 171 deserve nothing less.

Labor groups help 7 Myanmar nationals who died in car crash get compensation

Elon Musk's ministry says scholarship funding for Myanmar students is useless

A person who was responsible for studying and verifying the disputed border during the SPDC era said that it is difficult to say that the area that Thailand is demanding the Wa army camps to be removed is Myanmar territory.

The world's most haunted airport is Suvarnabhumi Airport, the beloved of the Burmese.

In Maha Chai, while a crane was loading an iron frame onto the Gong Kyaw Bridge under construction, it fell, killing 4, including 3 Burmese workers

BYD EVs with next-generation Blade batteries to debut in 2025

In South Korea, President Yoon Suk-yo has declared martial law

ကိုယ်တိုင်လက်ထိပ်ပြန်ခတ်ပြီး ဖမ်းဆီးခံရတဲ့ မလေးရှားရောက်မြန်မာတွေ

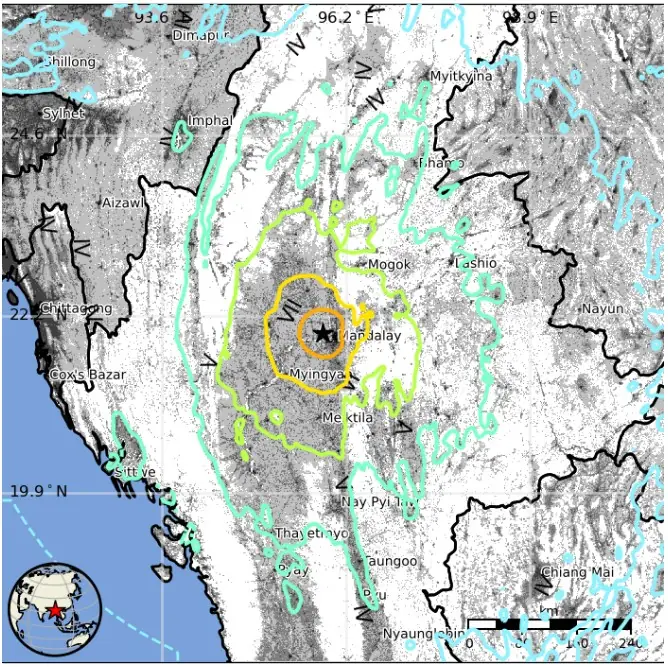

ငလျှင်ကယ်ဆယ်ရေးအဖွဲ့များရဲ့ ဖုန်းနံပါတ်